Gauges

Purlins are formed from sheet metal. A sheet metal gauge indicates the standard thickness of sheet metal for a specific material. As the gauge number increases, the material thickness decreases. Metroll offers:

10GA

12GA

14GA

16GA

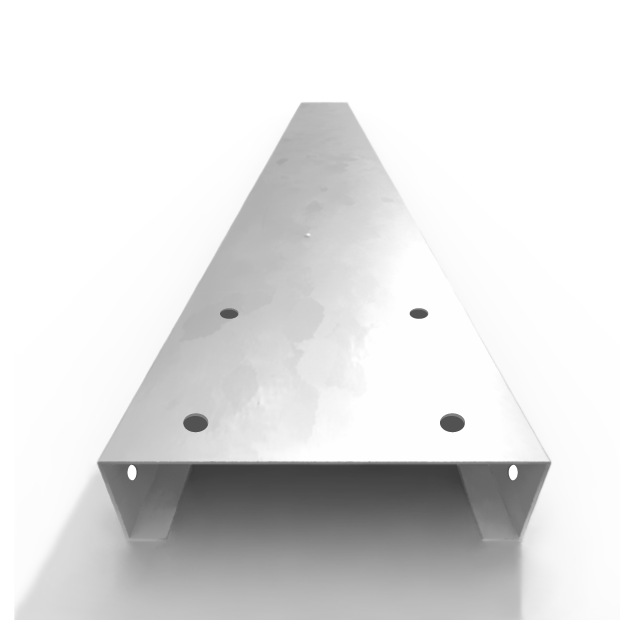

Web and Flange

Web and flange (2) measurements are required to order purlins.

Min. Web = 4"

Max. Web = 24"

Min. Flange = 2.5"

Max. Flange = 5"

Available Punch Sizes

Circle Punch

5/16” (Solar)

7/16”

9/16”

11/16”

5/8”

1-1/16”

3/8”

Slotted (Oval) Punch

5/8” x 3/4”

5/8” x 11/32”

3/8” x 7/8”

How to Order Cee Purlins

1. Purlin Profile

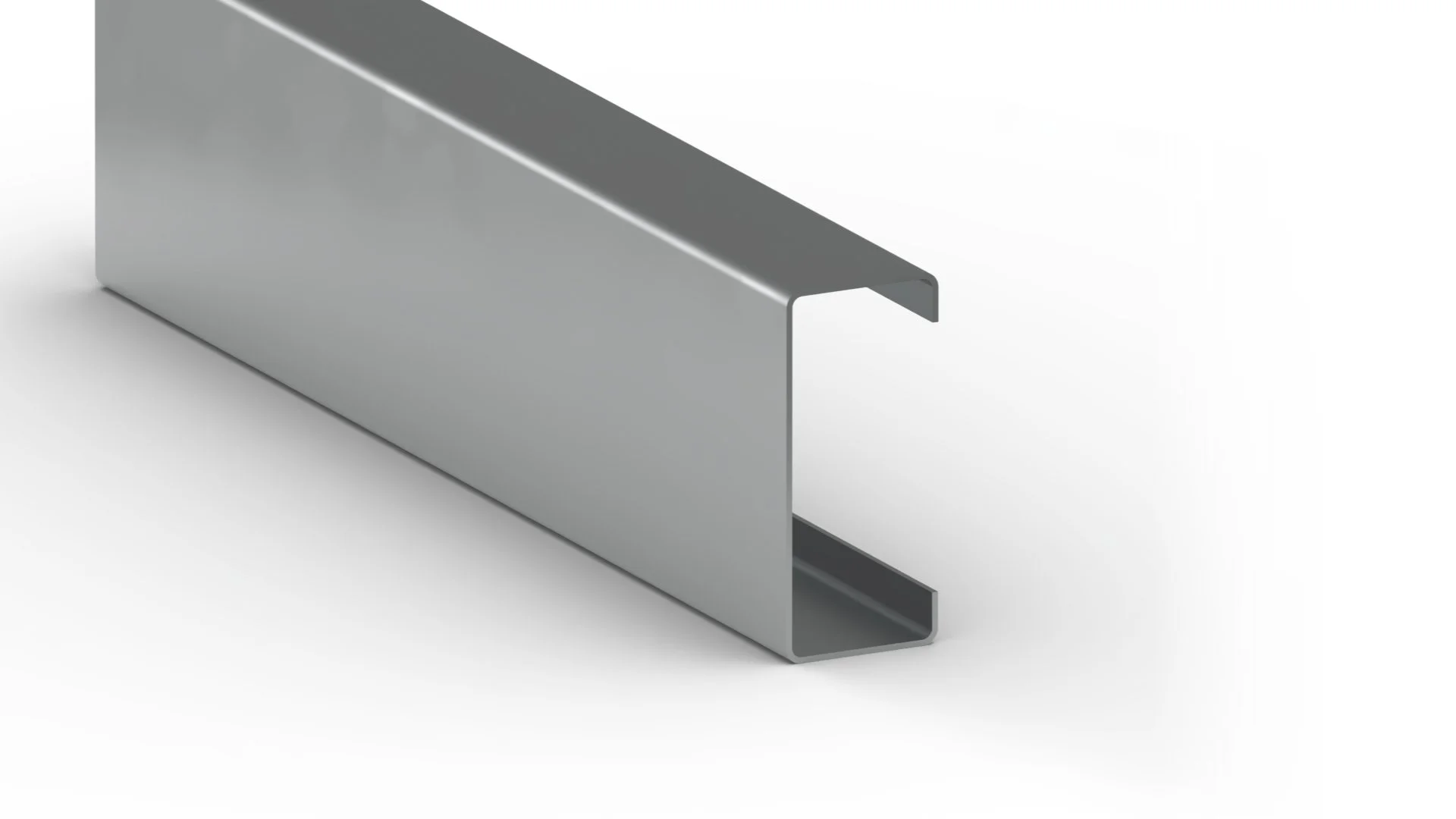

Cee Purlin or Zee Purlin? A Cee Purlin is NOT a C-Channel, C-Purlins have a lip

2. Gauge

How thick do you need your material?

We offer a variety of gauges for our custom-made purlins to cater to different structural requirements. You can choose from the following available gauges: 10GA, 12GA, 14GA, and 16GA. These gauges are carefully selected to ensure the strength and stability of your roofing or structural systems. By providing multiple gauge options, we aim to provide you with the flexibility to select the most appropriate purlins that align with your project specifications and desired level of durability.

3. Web and Flange

Web and Flange measurements are required to order purlins.

Min. Web = 4"

Max. Web = 24"

Min. Flange = 2.5"

Max. Flange = 5"

4. Length

How long can you custom-make your purlins?

We offer custom-made purlins with a wide range of length options to suit your specific needs. Depending on the gauge, our purlins can be manufactured starting from a minimum length of 6 feet and can go up to a maximum length of 50 feet. This allows for flexibility in designing and constructing your roofing or structural systems. Our goal is to provide you with tailored purlin solutions that meet your project requirements and ensure optimal performance and durability.

5. Punch

Punch or No Punch Purlin Option

We offer the flexibility of producing purlins with or without punches to cater to different construction project needs. Punched purlins have strategically placed holes or slots for easy installation and attachment of accessories, while unpunched purlins provide versatility for on-site adjustments. Our goal is to accommodate a wide range of requirements and provide you with the choice of purlins that best suit your project.